Case Studies

View our recent projects and case studies

Hosico has remained at the forefront of its market since foundation. Its continued focus on improvement, new technology, best-in-class and, where required, cutting edge engineering methodologies adapted to complex volume manufacture, will continue to see Hosico service its diverse client base now and in the future.

Click on one of our case studies below to learn more about the projects we’ve worked on.

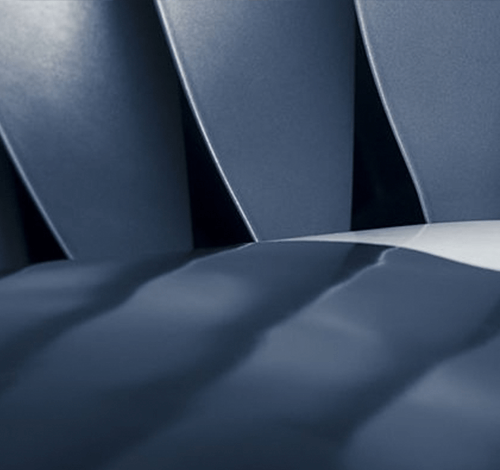

Case Study – Precision Decorative Casting

A leader in the Australian and Asia-Pacific electronic entertainment industry engaged Hosico to assist with the design and manufacture of their next-generation product, with the added pressure of ensuring delivery in an extremely short timeframe. This high-profile customer is known... Learn More

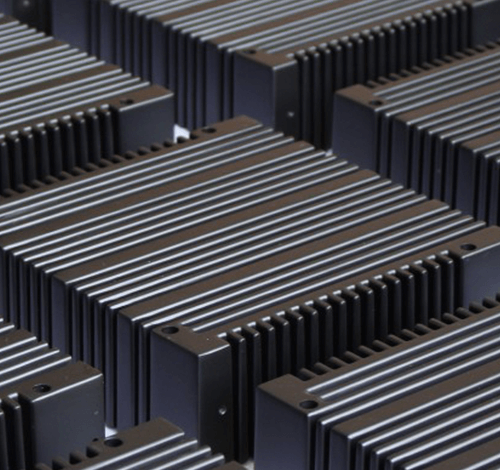

Case Study – Mission Critical Manufacturing

A purchaser of mission-critical componentry demands engineering and process excellence from its service and solutions providers. Hosico is one of a select group of Australian companies contracted by the end-user, via its specialist sub-contract suppliers, to manufacture mission-critical components and... Learn More

Case Study – Biomedical

Biomedical products and solutions demand precision and quality. One German company, a leader in the field of automated pathology diagnostics, had very specific requirements when looking to source consumables for their next-generation laboratory platform. Simply put, they required exceptional quality,... Learn More

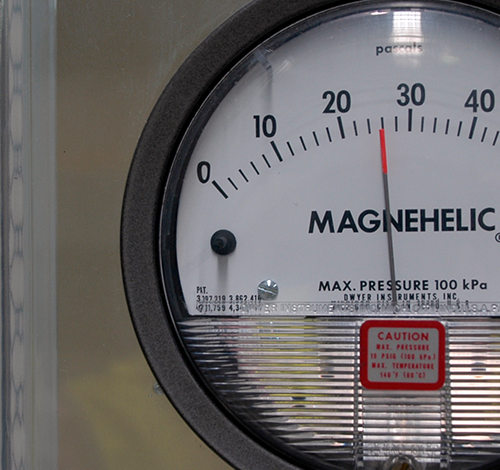

Case Study – Clean Room

An international market leader in the design and manufacture of complex Life Safety environmental monitoring solutions approached Hosico to lead a project to rationalise its supply chain – specifically the outsourcing of the manufacture and supply of critical laser-based optical... Learn More